Would you like to generate stock orders automatically?

Setting Up

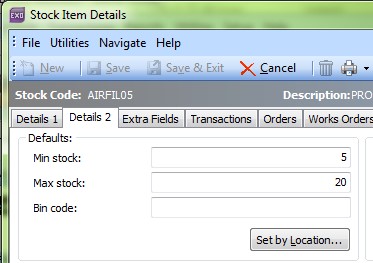

The first step involves you going through your stock items and setting up the minimum and maximum levels on the Details 2 tab for any Stock Item that you wish to generate Forecast Based Purchase Orders for.

If you want to set the same minimum and maximum for every location, set it in the above boxes.

If you want to set different minimum and maximum levels for each location do it by clicking on the “Set by Location” button (but leave the above fields blank)

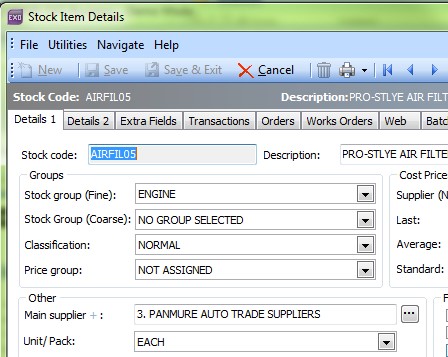

The next step is to make sure that your stock items have a “Main Supplier” set up on the Details 1 tab.

Once all of the required stock items have been set up, you are now ready to generate Forecast Based Purchase Orders.

Generating Forecast Based Purchase Order

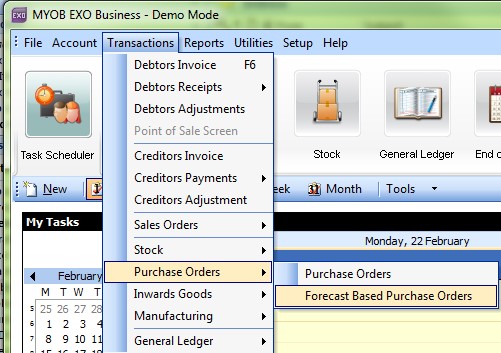

To create a Forecast Based Purchase Order follow the screen shot below.

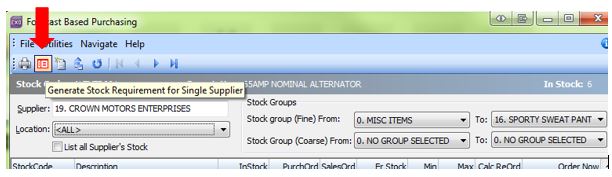

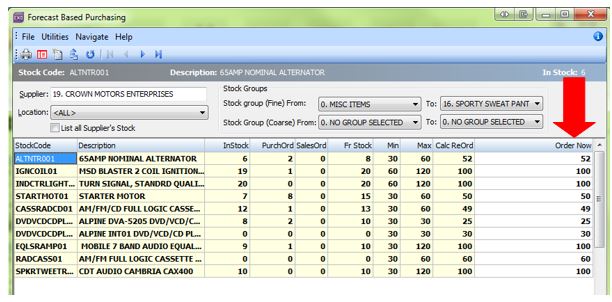

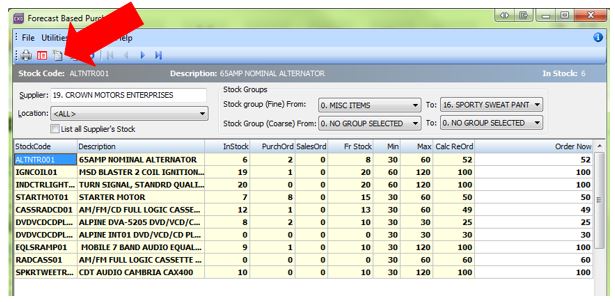

The screen below will pop up. From here, choose the supplier you would like to create a purchase order for then click on the button as displayed below.

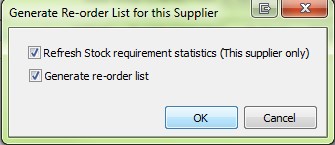

Leave the above check boxes checked and click OK.

The system will then calculate what items you require for the selected supplier.

You can change the amount you wish to Reorder in the “Order Now” column, rather than accepting the system generated quantity.

If you are happy with what the system wants to order, click on the “create purchase order” button.

Click Yes to the message below.

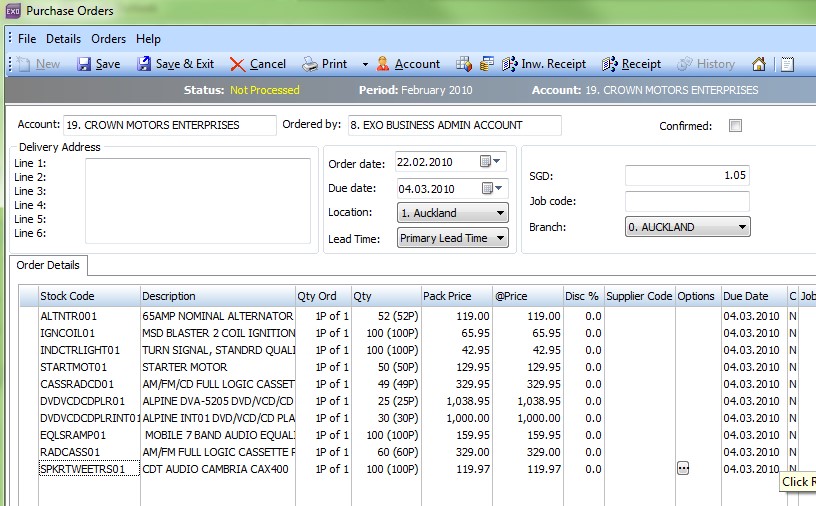

The system will then apply what is on the Forecast Screen to an actual Purchase Order. If you are happy with it, you can then click Save and Exit and send the purchase order to your supplier by your desired method.

The system will then apply what is on the Forecast Screen to an actual Purchase Order. If you are happy with it, you can then click Save and Exit and send the purchase order to your supplier by your desired method.

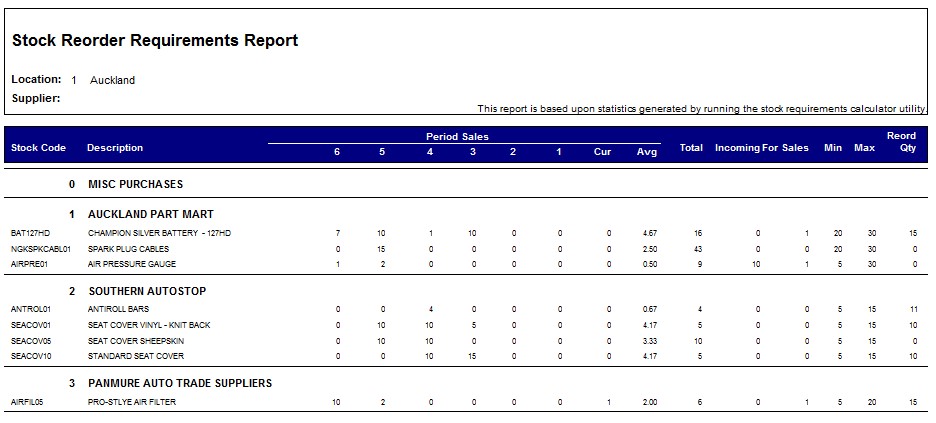

Reporting on a Recommended Reorder List

You can also generate a report showing recommended re-order levels for all suppliers.

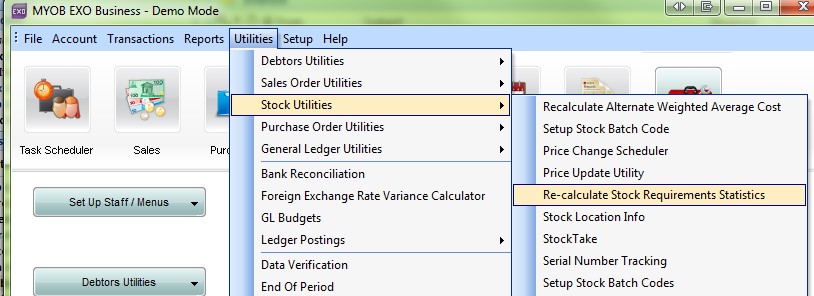

To do this, first run the “Stock Requirements Statistics” calculator:

This tool pre-calculates a recommended re-order quantity for your stock based on Minimum and Maximum stock counts.

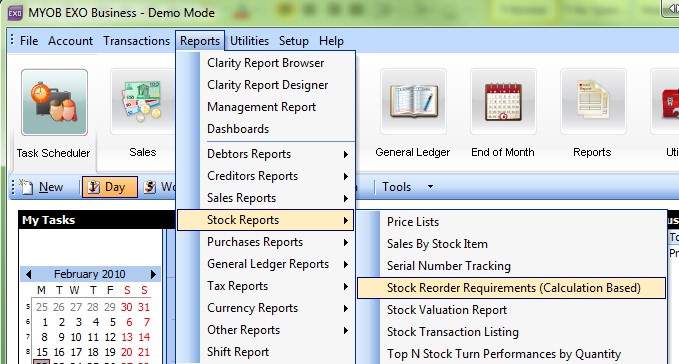

Once the system has calculated this you can then go and run the below report to see what the system recommends that you order.

Once the system has calculated this you can then go and run the below report to see what the system recommends that you order.

(NB – The Exo standard method of calculating the stock re order requirement can be quite slow. We have customised this calculation so that it runs much faster. If you find this occurs on your own system then talk to us. We can apply our customised option for a small fee)